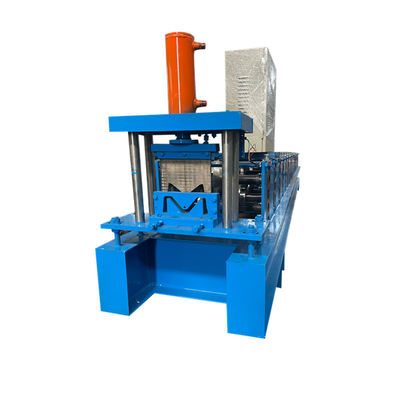

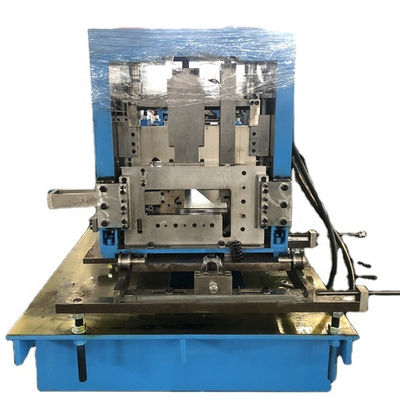

Main Roll forming for Galvanized steel rolling shutter door roll forming making machine

Roller station: as profile design

Roller material: No.45 steel with heat treatment , chrom on surface , hardness 58-60 .

Drive : chain or gear box

Motor : 5.5KW.